Needless to say that the hottest issue in the cement industry is to minimize the carbon footprint of cement production. In this direction, so many efforts are being spent. One of the latest innovation in this subject is using solar power as an alternative source to fossil fuels. Thanks to Bill Gates, this project came onto the agenda. Still the current level is not sufficient for cement production, but the project is very promising for the future.

Let’s review some articles about this innovation in terms of the cement industry.

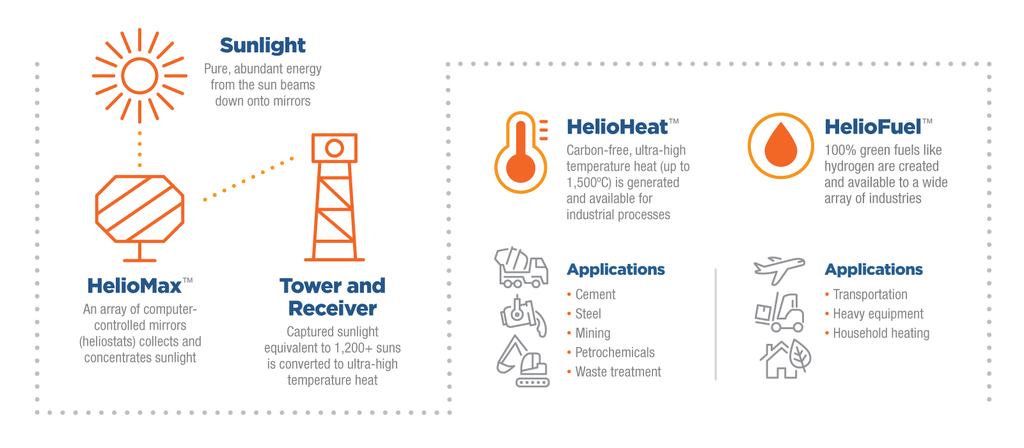

One of the hindrances of solar energy has long been that current solar panel technology cannot produce the very high temperatures needed to power industrial processes such as making cement, glass or steel.California-based Heliogen might soon change all of that. The startup has been working secretly on a solar “oven” that can generate temperatures over 1,000 degrees Celsius. Based on CSP (concentrating solar power), this oven sees hundreds of solar mirrors redirect sunlight toward a steam turbine.

The energy from the sun superheats water into steam that generates power. By finding a powerful backer—Bill Gates—Heliogen is committed to improve CSP technology.

Once Heliogen can produce temperatures of 1,500 degrees Celsius, it could produce an immediate zero-carbon alternative for heavy industries. This is not negligible when considering cement production alone accounts for a sizable amount of all carbon emissions.

In 2015, for example, the cement industry emitted 2.8 billion tons of carbon, accounting for 8% of all global emissions. This dwarfs that of the airline industry (2.5%) and almost rivals the emissions from agriculture (11%).

Without innovations to make its production cleaner, the impact of cement to greenhouse gases is unlikely to drop, especially since global use of cement is actually accelerating. The international concrete and cement market grew at an average pace of 7% from 2014 to 2018, and is estimated to speed up to 11% a year through 2022, boosted by the housing demand and low-interest rates for mortgages in developed countries.

Various ways have been suggested to lower the emissions from cement such as using cleaner, alternative materials in its production, making more efficient cement kilns or powering them with biofuels. But Heliogen’s advances are still one of the more notable advances.

The “solar oven” built by Heliogen in the Mojave Desert in California is comprised of 400 solar mirrors (heliostats), each equipped with an algorithmic conductor that directs sunbeams to a target on a nearby tower. The tower itself, described as “an industrial eye of Sauron”, collects sunlight at temperatures of 1,800 degrees Celsius—”roughly a quarter of the surface temperature of the sun”.

This scorching heat can then be applied to heavy industrial processes, providing the energy necessary to make cement, steel or glass. The appeal is evident—replacing the fossil fuels and heavy emissions of the current cement industry with clean energy would make this technology a potential show-stopper. “We are rolling out technology that can beat the price of fossil fuels and also not make the CO2 emissions,” explained Bill Gross, Heliogen’s founder and CEO to CNN Business. “And that’s really the holy grail”.

Heliogen has already installed a small cement oven atop the Heliomax tower to prove that limestone can be broken down into lime and carbon dioxide and later reassembled into cement, along with other materials. It worked, although a first attempt was successfully carried out by Solpart, a French-based effort, in 2018.

Source: https://www.eni.com/en-IT/low-carbon/solar-oven-more-sustainable-cement.html

Solar researchers at the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) have investigated how solar energy can replace fossil fuels for the cement production process. The initial manufacturing stage, the calcination of raw cement powder, has been successfully tested using a rotary kiln in the solar simulator at the DLR Institute of Solar Research in Cologne. Cement is one of the world’s most used commodities. Its production requires high temperatures that are predominantly produced by burning fossil fuels. The ‘solarisation’ of this process would therefore make a significant contribution to the reduction of global emissions.

Source: https://www.dlr.de/content/en/articles/news/2019/01/20190201_sustainable-cement-production.html

Suggestions for further reading:

Heliogen – Replacing Fuels with Sunlight

A Solar ‘Breakthrough’ Won’t Solve Cement’s Carbon Problem

Heliogen’s 1000C solar-heating technology could be key to low-emission cement

Solar-powered cement production

This Bill Gates-backed solar tech could help finally decarbonize heavy industry

Sustainable cement production – can concentrated solar power replace fossil fuels?